Proud of our innovations dedicated to our customers, we are attached to provide our leadership and homemade knowledge.

Customer’s satisfaction is our.

Faithful to his habits, Lagarde knew how to understand, study and propose computer systems for a long time without noisy communication in order to facilitate digital convergence and connect many objects and organizations between them.

However, a 4.0 Industry approach is a holistic approach that requires a global approach, not only based on new technologies accessible from all in the end.

The new technologies that you pay cannot alone solve your productivity and quality concerns.

First of all, you have to think about the objectives to be achieved by investing.

What do we want to solve, improve? Efficiency? Traceability? Product quality? Organization?

Collecting data is good, doing something with it is better!

You have to make sure you have the material resources for it. What computer equipment? What space?

The new technology must meet the company’s prerequisites with the quality of the products to be released, the safety of internal stakeholders, and data protection.

Digitization has a significant ecological footprint too.

Finally, it always requires new skills, either externalized (trust and dependence) or internal (recruitment and retention) and in both cases new expenses.

To conclude, it is about identifying the true direct, indirect, T.c.o cost and being able to assess at least theoretically the return on investment, the risk being to spend superfluously otherwise.

So we are at your disposal to help you in this process, but not at any cost for all of us, for the planet.

Let us speak together modestly, without haste and hindsight in the face of the challenges.

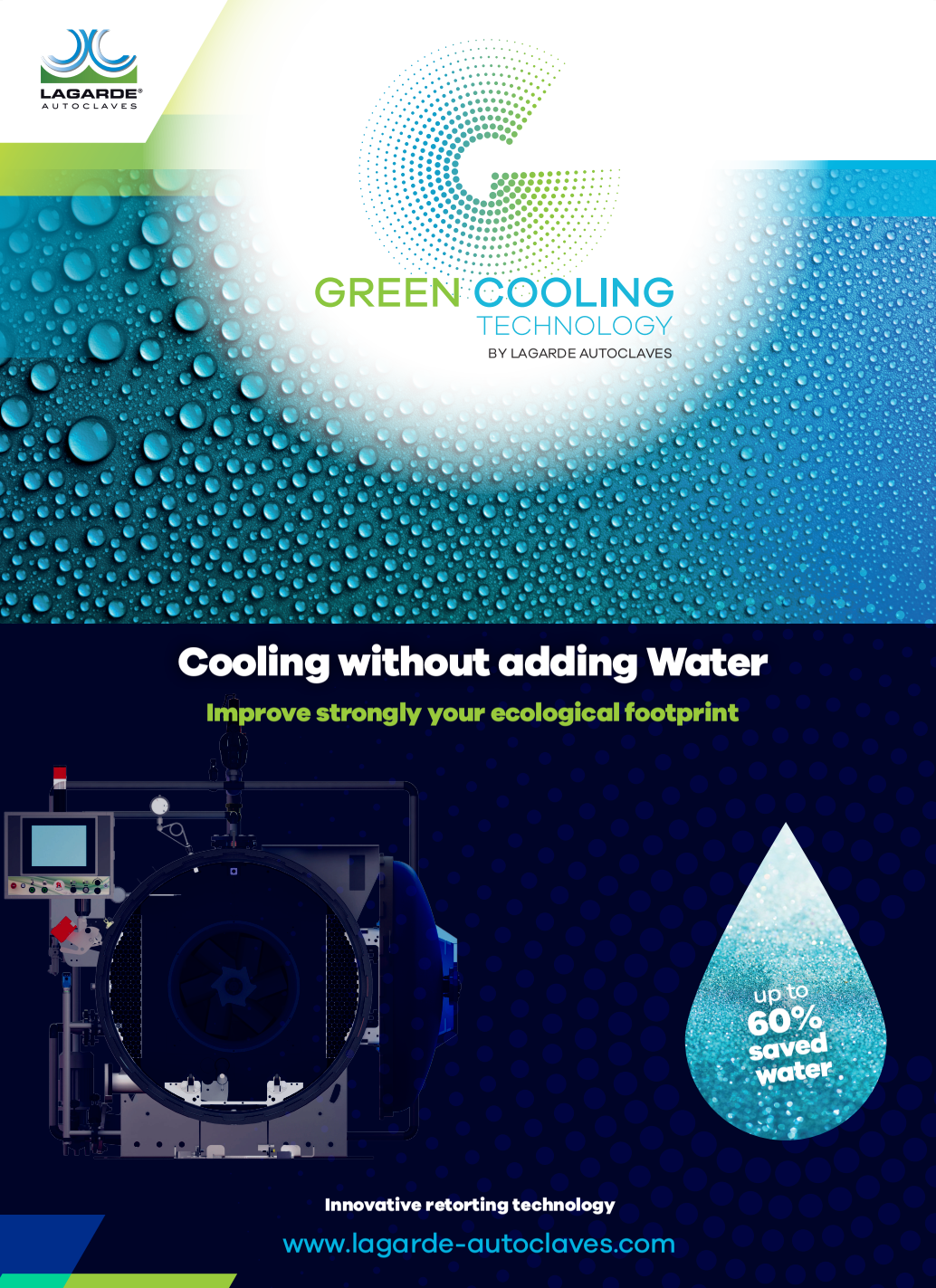

Because you don’t need to add process water* for cooling

60% of water is saved

Water which you use is already paid with steam – Recovering condensates

None extra cost on machine price